6x Node Bus Hub Assembly Guide

Table of contents

Table of contents

Introduction

The Node Bus Hub is a PCB whose primary function is to serve as a backbone for connecting the project’s LCC Fusion Node Card with multiple I/O Cards (PCBs), allowing them to communicate with each other and work as a unified system. This setup is commonly found in computers, servers, telecommunications equipment, and other electronic systems where modularity and scalability are important.

See the How to Use Assembly Guides for detailed instructions.

flowchart LR;

can["CAN Network"];

hub["Node Bus Hub <br/>(6x cards)"];

hub2["Node Bus Hub <br>(6x cards) <br/> (expansion)"];

n["Node Card"];

pc["Power-CAN Card"];

iocards["I/O Cards"];

iocards2["I/O Cards"];

subgraph layout ["Train Layout"];

direction LR;

can --> n --> hub;

can --> pc;

pc --> hub;

hub --> iocards --> devices((Devices));

hub --> |"Network Cable, or <br/> Direct Connection <br/> (unlimited daisy chaining)"| hub2;

hub2 --> iocards2 --> devices2((Devices));

end

classDef lSalmonStyle fill:#FFA07A,stroke:#333,stroke-width:2px,font-size:24px;

class hub,hub2 lSalmonStyle;

classDef lightGrayStyle fill:#d3d3d3,stroke:#333,stroke-width:2px,font-size:24px;

class layout lightGrayStyle;

Hub Connectors

All Node Bus Hub PCBs contain one or more Edge Card Connectors used to hold the cards in place and provide connectivity to the LCC Fusion Node Bus Hub, a set of 12 contacts providing power (GND, 3V3, 5V, 12+V) and communications ( I2C, CAN, and DCC). Below is the layout of the LCC Fusion Node Bus Hub connection pabs (left to right, refer to picture on the right):

All Node Bus Hub PCBs contain one or more Edge Card Connectors used to hold the cards in place and provide connectivity to the LCC Fusion Node Bus Hub, a set of 12 contacts providing power (GND, 3V3, 5V, 12+V) and communications ( I2C, CAN, and DCC). Below is the layout of the LCC Fusion Node Bus Hub connection pabs (left to right, refer to picture on the right):

| PCB Layer | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Top | 3V3 | 5V | 12 VDC | GND | SDA0 | SCL0 |

| Bottom | SCL1 | SDA1 | CAN-H | CAN-L | DCC1 | DCC2 |

Hub Expansion

Optionally, Node Bus Hub can provide additional connections for expansion with additional Node Bus Hub as follows (e.g. 6x Hub);

- For connecting to a remote Node Bus Hub, network cables (CAT5/6) RJ45 sockets may be provided allowing for daisy chaining over any distance.

- For direct connections to adjoining Node Bus Hub(s), sets of connections may be provided on the edges.

Hub Expansion Options

| Option | Description | Advantages | Disadvantages |

|---|---|---|---|

| Board-to-Board Connectors (Headers) | Use headers to connect adjacent hubs directly. | Secure mechanical and electrical connection; minimal additional components; vertical and horizontal Hub arrangements; No Hub cables required | Limited flexibility in positioning; requires larger foot print |

| Network Cables | Use standard network cables (e.g., Ethernet cables) to connect hubs. | Flexible positioning; easy to extend the network; uses common cables for communications and power | Requires cabling between Hubs |

| WiFi | Utilize the LCC Fusion I/O Controller Card to provide inter-Hub connections. | No cabling between Hubs; Easy repositioning of Hubs | Requires an I/O Controller Card and use of one Hub connector; Potential issues with signal range and interference; requires power to the Hub via the I/O Controller Card. |

| Hybrid Approach | Combine board-to-board connections for nearby hubs and network cables or wireless connections for distant ones. | Balances the stability of wired connections with the flexibility of wireless | Complexity in managing different connection types; potential for signal integrity issues |

| Modular Network Design | Design your hub assemblies to support modular network connections, allowing for easy reconfiguration. | High flexibility and scalability; future-proofing | Initial design complexity; potential for higher cost |

Assembly-Configuration Options

The 6x Node Bus Hub supports multiple assembly configurations to fit various use cases.

| Configuration | Required/Optional | Description | Required Components | Optional Components |

|---|---|---|---|---|

| LCC Fusion Card Support | Required | Provides connectors for the Node Card, Power-CAN Card, and other I/O Cards | Card Edge Connector: J1 | • Card Edge Connector: 805 card edge connectors J2 - J6 |

| I2C Bus Voltage Conditioning (Pullup) Automation Support | Required | Provides required I2C Bus 120Ω termination (when required) and | • Voltage Comparators (U1, U2, ZD1, R1, C1, C4) • Low Pass Filter: capacitors C2, C3, C5, C6, resistors R2, R3, R4, R5 • **120Ω Switching Circuit: Pullup Resistors** R6, R7, R8, R9, **Transistors Q1, Q2, Q3, Q4) |

None |

| I2C BUS Protection Support | Required | I2C Low Voltage Detection and Correction | • I2C Bus Protection: Diodes D5, D6 (for ESD protection on the I2Cdata bus) | None |

| CAN BUS ESD Protection Support | Optional | Provides ESD protection for CAN Bus | • CAN Bus Protection: Diode D7 (for ESD protection on the I2Cdata bus) | None |

| Node Bus Hub Expansion | Optional | Provides connectors to additional Node Bus Hubs vertically or horizontally | • Direct Connect Vertically: 8-Pin Male or Female Header J7, J8 • Direct Connect Horizontal **: 8-Pin Male or Female Header **J11, J12 • Remote Connector Tethered **: RJ45 8-Pin socket **J9, J10 |

|

| 5 VDC Output Support | Optional | Supplies regulated 5V via USB-C socket with reverse current protection | • 5V Regulated Output: connector J13, D4 | None |

| Indicators and Controls Support Option | Optional | Setup for Power ** and **I2C Data Indicators | • Power Indicator (LED1, R12) • I2C Data Transmission Indicators: LEDs LED2, LED3, current limiting resistors R13, R14, R10, R11, switching transistors Q5, Q6 |

None |

Assembly and Component Placement

This section combines both the component specifications and the assembly instructions to ensure a smooth assembly process. Below is a comprehensive list of components, their placement on the PCB, and orientation details to assist you during assembly.

High-Level Steps for Assembly:

- PCB for the card can be ordered from any PCB fabricator using these Gerber Files.

- Clean PCB with alcohol to remove residue. See Cleaning_PCB for details.

- See also: Soldering Tips

- PCB Components - listing of components used for PCB assembly

-

PCB Parts - listing of parts used for PCB assembly

- 6x-Node Bus Hub (use with up to 6 cards, with expansion capabilities with more 6x Node Bus Hubs, typically used in a central location). This implementation of the Node Bus Hub also provides:

- Selection for adding I2C pull-up for long I2C serial connections to improve signal quality.

- Network cable connections (RJ45) to allow expansion to additional Node Bus Hubs.

- Connectors (female pin headers) to allow expansion to additional Node Bus Hubs.

- LED indicators for I2C data transmission for BUS A and BUS B. A transistor is used to trigger the LEDs to sense data transmissions from the I2C TX (transmission) line going HIGH during data transmissions.

- 5V power supply connection (USB-C) for providing power when the expansion board is not being powered by a Primary LCC Fusion Node Card (with a Power Module).

- Depending on requirements, 1 to 6 connectors can be installed on either side.

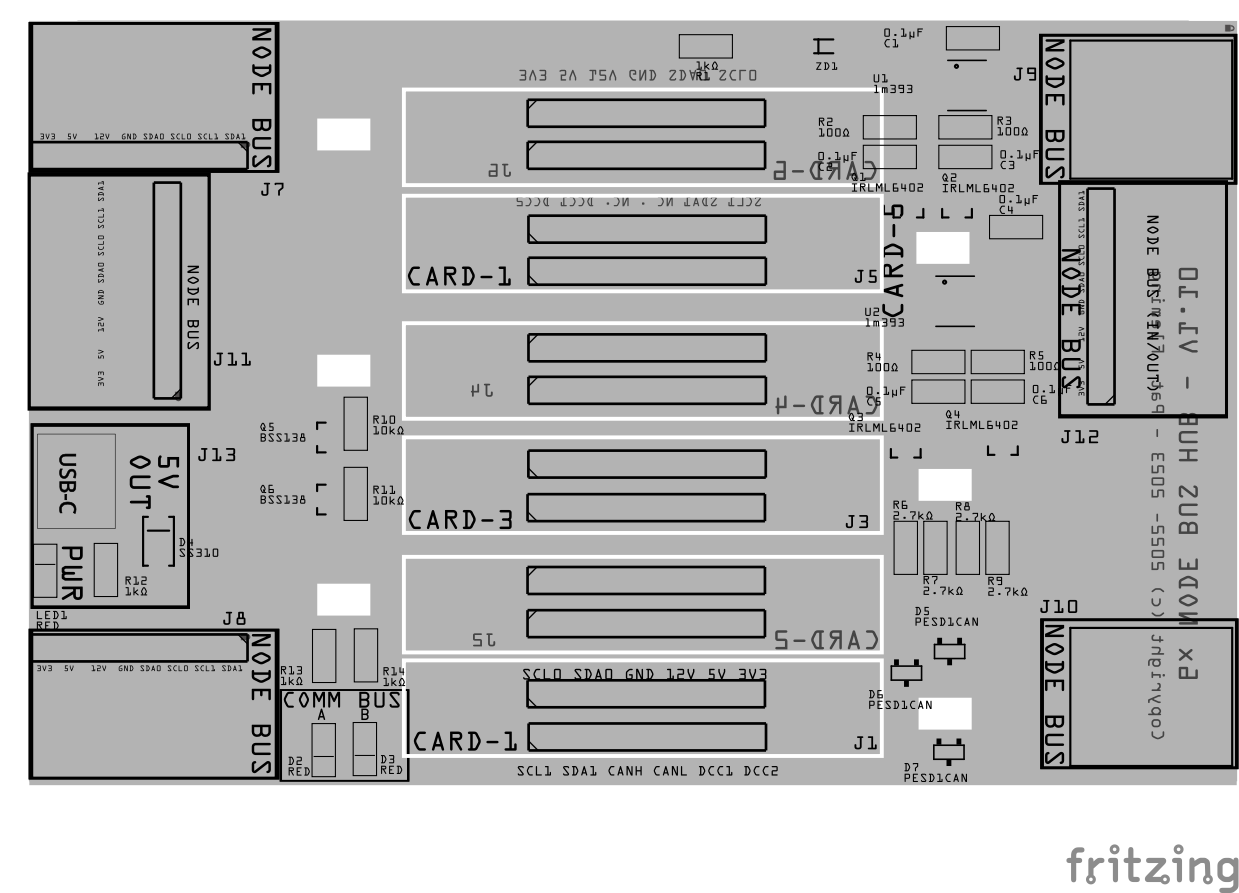

Below is a list of the PCB components used for the 6x Node Bus Hub (see diagram on right for reference):

| Component Identifier | Count | Type | Value | Package | Purpose | Orientation |

|---|---|---|---|---|---|---|

| Capacitors | ||||||

| C1, C4 | 2 | Capacitor-Ceramic | 0.1uF | SMD 1206 | Conditions/filters the current for the IC (U1, U2). | None |

| C2, C3, C5, C6 | 4 | Capacitor-Ceramic | 0.1uF | SMD 1206 | Low Pass Filter for low signal detection | None |

| Diodes | ||||||

| D4 | 1 | Diode-Schottky | SS310 | SMA | Prevents accidental input VDC+ from damaging circuits, since USB-C is output-only. | Cathode end has a white line and positioned towards PCB top edge |

| D5, D6 | 2 | ESD Diode | PESD1CAN | SOT-23 SMD | Required only when using the I2C data bus. Provides I2C electrostatic discharge (ESD) protection. | Fits only one way |

| D7 | 1 | ESD Diode | PESD1CAN | SOT-23 SMD | Provides CAN Network data bus electrostatic discharge (ESD) protection. | Fits only one way |

| ZD1 | 1 | Diode-Zener | 2.4 VDC | BZT52 | Used for a 2.4 VDC reference voltage | Cathode end has a white line and positioned towards PCB left edge |

| Connectors | ||||||

| J1-J6 | 6 | Card Edge Connector | 12P (2x6) | 3.96mm, 805 Card Edge Connector (PTH) | Connector for inserting cards with card edge connector tabs. Number of connectors varies by Node Bus Hub design. | N/A |

| J7, J8, J11, J121 | 4 | Female Right Angle Header | 8P, 2.54mm | - | Used for connecting boards via pin headers. Provides direct connection to adjoining Node Bus Hub PCBs for I/O expansion. | Position towards PCB outer edge |

| J9, J10 | 2 | RJ45 Socket | 8P8C | - | Required only when connecting hubs together using network cables. Provides network cable (CAT5/6) connection(s) to remote Node Bus Hub PCBs. | Fits only one way |

| J13 | 1 | Male Pin Header | 2P | - | Used to enable/disable I2C pullups for better reliability within a Node Bus Hub. Typically set once per hub. | None |

| J14 | 1 | Connector | USB-C, 4P | - | Required only when not using Power-CAN Card for power. Provides 5V power to remote devices. | Position towards PCB outer edge |

| Indicators | ||||||

| LED1-LED3 | 3 | LED | Red | SMD 1206 | Indicators for PWR (5 VDC) and I2C data transmission (receive (RX) line) | Reference back of LED, position cathode towards PCB top |

| Transistors | ||||||

| Q1-Q4 | 4 | PNP Transistor | IRLML6402 | SOT-23-3 | Controls I2C Bus A/B 2.7k pullups when triggered by comparator | Fits only one way |

| Q5, Q6 | 2 | NPN Transistor | BSS138 | SOT-23 | Used to turn on I2C data transmission indicators based on I2C signals. | Fits only one way |

| Resistors | ||||||

| R1 | 1 | Resistor | 1kΩ | SMD 1206 | Current limiting for reference voltage | None |

| R2 - R5 | 4 | Resistor | 100Ω | SMD 1206 | Low Pass Filter for low signal detection | None |

| R6-R9 | 4 | Resistor | 2.7kΩ | SMD 1206 | I2C Pullup resistors for both sets of SDA/SCL lines. Improves signal quality. | None |

| R10, R11 | 2 | Resistor | 10kΩ | SMD 1206 | Current limiting resistors for I2C indicators. | None |

| R12 | 1 | Resistor | 1kΩ | SMD 1206 | Current limiting resistors for power indicator | None |

| R13, R14 | 2 | Resistor | 1kΩ | SMD 1206 | Current limiting resistors for LED I2C indicators. | None |

| ICs | ||||||

| U1, U2 | 2 | IC (Voltage Comparator) | LM393 or LM2903N | SO-8, SMD | Used for detecting low voltage in the I2C lines (less than 2.$1 VDC) | IC’s dimple (pin 1) positioned toward PCB top edge |

| U3, U4 | 2 | I2C Repeater | PCA9515A | TSSOP-8, SMD | Used to buffer I2C into segments for longer cabling runs | IC’s dimple (pin 1) positioned toward PCB top edge |

- 8-male header when connecting boards together via pin headers between the optional female headers (J8, J9, J11, J12). Connects to adjoining Node Bus Hub together by connecting the female right angle connectors together.

Tools Required

The card only requires soldering three sets of PTH female pin headers. Required tools required are:

- soldering iron

- solder

- tacky putty (hold components while soldering)

See List of recommended tools for more details on these tools.

Safety Precautions

Testing and Verification

The following test and verifications of the card should be performed after a through inspection of the card’s soldering. Check all of the PTH component pins. Make sure there are no solder bridges between pins.

Visual Inspection

- Initial Check: Examine the board for any obvious issues like missing components, solder bridges, or components that are misaligned or not fully seated.

- Solder Joint Inspection: Use a magnifying glass or a microscope to inspect solder joints. Look for cold solder joints, insufficient or excessive solder, or any shorts between pads.

Power-Up Tests

Refer to the LCC Fusion Node Card for details on testing the LCC Fusion Node Bus Hub

Troubleshooting

- See I2C Trouble Shooting.

Appendences

PCB Specifications

Specifications for the Node Bus Hub include:

| Characteristic | Value |

|---|---|

| Max Cards | 6 |

| Min Input | 3A |

| Input / Output | 3V3, 5V, 12 VDC |

| Max Input | 35 VDC |

| Hardware Communication Buses (I2C) | 2 |

| CAN (Controller Area Network) | 1 |

| DCC (Digital Command Control) | 1 |

| Expansion Board Connectors | 4 |

- Power connections for 3V3, 5V, 12 VDC.

- MAX current 1.7A (based on 24 mil trace width, 1oz)

- MAX connectors; 6 (6x Node Bus Hub), 2 (2x Node Bus Hub)

- Indicators (6x Node Bus Hub); 5V (red), I2C data transmit (GRN), I2C data receive (RED)

How It Works

The LCC Fusion Project’s Node Bus Hub is a versatile PCB designed to streamline the connection and management of multiple LCC (Layout Command Control) devices in a model railroad automation setup. Here’s a detailed overview of its features and functionality:

- Card Edge Connectors: The Node Bus Hub is equipped with up to 6x 805 card edge 2x6 connectors. These connectors provide parallel connections for multiple critical signals and power lines, including:

- 3.3 VDC

- 5 VDC

- 12 VDC

- CAN (Controller Area Network)

- Two I2C (Inter-Integrated Circuit) buses

- DCC (Digital Command Control)

-

RJ45 Sockets and Pin Headers: The PCB includes RJ45 sockets and pin headers that allow for easy interconnection of multiple hubs, enabling flexible expansion and connectivity between different parts of the layout.

-

LED Indicators: The hub features LED indicators for monitoring the I2C bus status. These LEDs provide visual feedback on SDA (Serial Data Line) transfer activity, helping users quickly identify any communication issues.

-

BSS138 Transistor: A BSS138 MOSFET transistor is integrated into the circuit, assisting with I2C bus communication and particularly with LED status indication. This component ensures reliable signal level shifting and smooth operation of the I2C buses.

-

USB-C Power Option: For testing purposes without a Power-CAN Card, the Node Bus Hub can be powered via a 5V USB-C connection. This feature includes a power indicator LED and reverse flow protection to prevent any potential damage from incorrect power flow.

- Communication Protection: To protect the communication lines, the Node Bus Hub utilizes PESD1CAN protection devices for both I2C buses and the CAN network. These components help safeguard the hub and connected devices from electrostatic discharge (ESD) and other transient voltage spikes.

Automatic I2C Pull-Up Conditioning

The LCC Fusion Node Bus Hub includes automatic I²C pull-up conditioning to ensure robust and reliable communication across connected devices. This feature dynamically enables pull-up resistors only when needed, based on real-time voltage monitoring of the SDA and SCL lines, reducing unnecessary bus loading while maintaining signal integrity.

Each hub monitors its local I²C segment independently using a dedicated circuit consisting of an LM393 comparator, Zener voltage reference, and a PNP transistor (e.g., IRLML6402). The result is a self-regulating bus that stays stable across variable distances and device counts.

- Voltage Monitoring

- The SDA and SCL lines are continuously monitored by the LM393 comparator.

- Voltage on each line is compared to a fixed reference (~2.4 V) provided by a Zener diode.

- If the idle voltage is below this threshold, it indicates no other active pull-up is present on the segment, and the comparator activates the local pull-ups.

- Dynamic Pull-Up Activation

- When triggered, the comparator output drives the base of a PNP transistor.

- This connects 3.3 V through a 2.7 kΩ resistor to the affected I²C line (SDA or SCL), restoring proper voltage and line strength.

- Low-Pass Filtering

- A low-pass RC filter on the comparator input prevents false triggering due to high-frequency noise or normal I²C traffic.

- This ensures that only true idle line degradation activates the pull-up.

- I²C Line Stability

- The circuit only engages pull-ups when no other hub is maintaining the bus.

- This avoids redundant pull-ups that would unnecessarily lower the effective resistance and load the I²C master.

- Dual-Bus Monitoring

- Both I²C Bus A and I²C Bus B are supported independently.

- Each bus has its own comparator, Zener diode, transistor, and pull-up resistors, ensuring reliable operation across both communication paths.

This automatic pull-up system allows every LCC Fusion Node Bus Hub — including the 1×, 2×, and 6× variants — to intelligently manage its I²C segment. The result is improved I²C reliability in complex, daisy-chained layouts with unknown segment lengths or numbers of devices, all without requiring manual configuration or solder jumpers.

Connections

The purpose of the Node Bus Hub and its connectors is to facilitate quick and easy connections between the LCC Fusion cards. For setups with requiring expansion, the Node Bus Hub provides connections to additional hubs.

| Component Designator | Connector Label | Connector Type | Connection Number | Description |

|---|---|---|---|---|

| J1, J2, J3, J4, J5, J6 | CARD-1 to CARD-6 | Card Edge Connector | 1 - 6 | Connection to LCC Fusion Cards |

| J7, J8, J11, J12 | NODE BUS | Female Header | n/a | Connection to another Node Bus Hub using pin headers |

| J9, J10 | NODE BUS | RJ45 Socket | N/A | Connection to another Node Bus Hub using a network cable |

PCB Protection

| Protected Component | Protection Component | Function | Specifications | Location |

|---|---|---|---|---|

| I2C Connection | PESD1CAN Diodes | Protect against ESD (Electrostatic Discharge) from the CAN network lines | Reverse Stand-off Voltage (Vr): 24 VDC Clamping Voltage (Vc): 40 VDC |

Across each I2C line (SDA, SCL) input line and GND |

| CAN Connection | PESD1CAN Diodes | Protect against ESD (Electrostatic Discharge) from the CAN network lines | Reverse Stand-off Voltage (Vr): 24 VDC Clamping Voltage (Vc): 40 VDC |

Across each CAN line (CAN-H, CAN-L) input line and GND |

| Power Supply (USB-C Option) | Reverse Flow Protection | Prevents damage from incorrect power flow direction. | Reverse polarity protection | USB-C power input |

| I2C Buses | 2.7k Ohm Pull-up Resistors | Stabilizes I2C communication by providing additional pull-up resistance. | 2.7k ohm resistors | Activated via jumper cap |