Digital I/O Card & Breakout Board Installation Guide

Table of contents

Table of contents

Overview

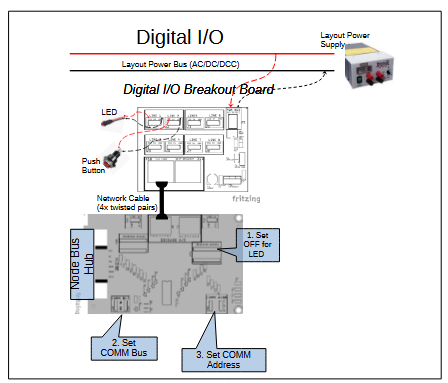

The Digital I/O Breakout Board interfaces the Digital I/O Card with up to eight digital input or output devices. It supports a wide variety of devices such as sensors, buttons, LEDs, and small actuators used in model railroad automation and other low-power control applications.

The board is powered from one of the layout’s power bus (AC, DC, or DCC), rectified via an onboard bridge rectifier, and regulated to a stable 5 VDC supply for the devices and board circuitry.

What’s Needed

| Component | Purpose |

|---|---|

| Computer / RPI (3B+)1 | Runs JMRI for CAN communications with Node Card |

| Node Card & Power Supply | Interfaces with CAN network and cards (via Node Bus Hub) |

| Digital I/O Breakout Board | Interfaces digital I/O signals and power for digital I/O devices |

| Digital I/O Card | Interfaces with Node Card via serial communications and converts digital I/O to signals for the Digital I/O Breakout Board. |

| Digital I/O Devices (8 max) | Sensors, buttons, LEDs, relays, or actuators |

| Network Cable (CAT5/CAT6) | Connects Digital I/O Card to Digital I/O Breakout Board via RJ45 connector |

| 3-wire cables | Connect devices to breakout board JST XH connectors |

| Layout Power Bus (AC/DC/DCC) | Supplies breakout board power (<40 VDC, AC/DC/DCC) |

1) When using an RPi, you can simplify integration by using the RPi-CAN Card, which provides built-in CAN communication and connects directly to the LCC Fusion Node Bus—no extra wiring required. Otherwise, to run JMRI on a standalone Pi you will need:

- Raspberry Pi 3B+ (or newer): Runs JMRI for CAN communications. We recommend Steve Todd’s preconfigured JMRI image

- microSD card (8 GB or larger): Holds the JMRI OS image

- microSD card reader & imaging tool: For flashing the image to your card (e.g., balenaEtcher)

Connection Diagram

flowchart

subgraph layout ["Train Layout"]

subgraph hub["Node Bus Hub"]

nodeCard[["Node Card"]]

ioCard[["Digital I/O Card"]]

end

jmri["JMRI Software<br>CDI Config Tool"]

computer["Computer, or <br>Raspberry PI"]

pwrSupply(("Power Supply"))

breakout1["Digital I/O <br>Breakout Board"]

breakout2["2nd Digital I/O <br>Breakout Board"]

devices1(("Digital I/O Devices (8x)"))

devices2(("Digital I/O Devices (8x)"))

pwrbus(("PWR BUS <br>(AC/DC/DCC)"))

end

jmri -.- |"runs on"|computer <--> |"CAN Bus via<br>Network Cable"|nodeCard

pwrSupply -.-> |"1+ A @ 40 v max via<br>2-wire"| nodeCard

nodeCard <--> |"Digital I/O via<br>Node Bus"|ioCard

ioCard <--> |"Digital I/O via<br>Network Cable → J10" |breakout1

breakout1 <-.-> |"I/O via<br>2-wire → J1...J8"|devices1

breakout1 <--> |"I/O via<br>Network Cable → J11" |breakout2

breakout2 <-.-> |"Digital I/O via<br>2-wire → J1...J8"|devices2

pwrbus <--> |"14+ VDC via<br>2-wire Cable → J9"|breakout1

classDef lightBlueStyle fill:lightblue,stroke:#2c7a2c,stroke-width:2px,font-size:16px;

classDef lightGreenStyle fill:lightgreen,stroke:#333,stroke-width:2px,font-size:20px;

class hub lightBlueStyle

class ioCard,breakout1,breakout2 lightGreenStyle

Installation Steps

Connect the Digital I/O Breakout Board to the Digital I/O Card using a standard network cable (RJ45).

Connect the Digital I/O Breakout Board to the Digital I/O Card using a standard network cable (RJ45).- Connect the layout Accessory Power Bus (AC, DC, or DCC) to the breakout board’s power input (J9).

- Connect up to eight digital devices to the breakout board’s 3-pin JST XH connectors:

- Pin 1: 5 VDC power (from board regulator, used for input device power)

- Pin 2: Signal line (digital input or output)

- Pin 3: Ground (common reference)

- Configure the Node Card firmware to set each I/O line as input or output as required by your application.

- Ensure wiring polarity and connections match device requirements — input devices expect power on Pin 1, output devices receive control signals on Pin 2.

Wiring Suggestions & Best Practices

-

Always connect device ground to Pin 3 (GND) for common reference.

-

For input devices (e.g., sensors, switches), connect device power to Pin 1 (5 VDC) and signal output to Pin 2 (Signal).

-

For output devices (e.g., LEDs, relays), device power is typically shared from the same 5 VDC rail; device control line connects to Pin 2, device ground to Pin 3.

-

Use shielded or twisted pair cables where possible to reduce noise on signal lines.

-

Avoid mixing input and output device connections on the same physical line without proper configuration to prevent damage.

-

Consult device datasheets for power and signal wiring requirements.

-

Ensure firm and secure connections to JST headers and network cables.

Device Type I/O Type Typical Wires Device Wire for 5V Pin Device Wire for SIG Pin Device Wire for GND Pin Notes Digital Sensor (e.g., proximity, IR) Input 3 VDC+ Signal (SIG) GND Sensor powered by 5 VDC; outputs digital signal Push Button / Switch Input 2 n/a Yes Yes Configure via CDI as Input with internal pull-up enabled LED (ON/OFF control) Output 2 n/a Anode Lead Cathode Lead Configure Digital I/O Card with 1kΩ current limiting resistor DC 5V Relay Module Output 3 VDC+ Signal (SIG) GND 5V Buzzer Output 2 n/a Yes Yes Simple ON/OFF control

Status Indicators

- Power LED: Illuminates when 5 VDC power is present and regulated on the breakout board.

Testing & Troubleshooting

- Cables & Connections

- Ensure the network cable between the Digital I/O Card and Breakout Board is fully seated and oriented correctly.

- Verify accessory bus voltage and polarity at the board’s power connector.

- Confirm device wiring matches the board pinouts (signal, VDC+, GND).

- Firmware & Diagnostics

- Use the LCC Configuration Monitor (JMRI), serial console, or other diagnostic tool to check that inputs register and outputs toggle as expected.

| Test | Check Point | Expected |

|---|---|---|

| Power LED | LED beside VR1 | LED is ON |

| PWR BUS Voltage | J9 VDC+ → GND | > 12 VDC (AC, DC, or DCC) |

| 5 VDC Regulator | J1–J4 VDC+ → GND | ≈ 5.0 VDC |

| Device Activation | Output lines 1–4 via J10 | Outputs switch on/off; inputs generate LCC Events |

| Daisy-Chain I/O | Lines 5–8 via J11 | Same results on lines 5–8 |

🧰 Troubleshooting Flow

Refer to the Output Device Flow and Input Device Flow diagrams for step-by-step guidance on isolating wiring, power, firmware, and device issues. If you reach a “Likely Bad Board” node, set the board aside for bench testing or builder support.

Output Device Text Flow

flowchart TD

subgraph "Output Device Test Flow"

direction LR

Connect-Power("Connect supply power to <br>PWR BUS connector (J5)")

Connect-Card("Connect <br>Digital I/O Card")

Connect-Device("Connect <br>output devices <br>(lamps, LEDs)<br>to connectors <br>(J1–J8)")

Activate-Device("Activate input <br>device (LCC Event)")

Activate-Input-Line("Bypass Digital <br>I/O Card: <br>Apply 5 V to each <br>input line (J6)")

LED-Q{"Is the Power LED ON?"}

PWR-Q{"Measure input at PWR BUS (J9).<br><br>Is voltage >14 V?"}

Device-On-Q{"Do connected devices <br>turn ON correctly?"}

Input-Test-Q{"Does the <br>corresponding <br>device turn ON?"}

Success[[" Installation <br>Successful"]]

Connect-Power --> LED-Q

LED-Q -- "Yes, power LED is On" --> Connect-Card --> Connect-Device --> Activate-Device --> Device-On-Q

LED-Q -- "No, power LED is Off" --> PWR-Q

PWR-Q -- "Yes, valid input power" --> Bad-Board

PWR-Q -- "No, invalid input power" --> Fix-PWR

Fix-PWR["Check layout <br>power wiring, <br>power supply <br>voltage"]

Fix-CDI["Verify card is good. <br>Check cards's <br>CDI configuration"]

Fix-Device["Check device <br>wiring, polarity,<br>or replace device"]

Bad-Board["Likely bad <br>Digital I/O<br>Breakout Board <br><br>Contact builder"]

Device-On-Q -- "Yes, device working" --> Success

Device-On-Q -- "No, device not working" --> Activate-Input-Line --> Input-Test-Q

Input-Test-Q -- "Yes, device works without <br>Output Card" --> Fix-CDI

Input-Test-Q -- "No, device not working" --> Bad-Board

end

%% Color styles

classDef question fill:#d3d3d3,stroke:#333,stroke-width:2px,font-size:16px;

classDef error fill:#FFA07A,stroke:#333,stroke-width:2px,font-size:16px;

classDef success fill:#c6f6c6,stroke:#2c7a2c,stroke-width:2px,font-size:16px;

classDef action fill:lightblue,stroke:#2c7a2c,stroke-width:2px,font-size:16px;

class LED-Q,PWR-Q,Relay-Click-Q,Input-Test-Q,Device-On-Q question;

class Fix-PWR,Fix-CDI,Fix-Device,Bad-Board error;

class Connect-Power,Connect-Card,Connect-Device,Activate-Device,Activate-Input-Line action;

class Success success;

Input Device Test Flow

flowchart TD

subgraph "Input Device Test Flow"

direction LR

Connect-Power("Connect supply power to <br>PWR BUS connector (J5)")

Connect-Card("Connect <br>Digital I/O Card")

Connect-Device("Connect <br>input devices <br>(buttons, sensors)<br>to connectors <br>(J1–J8)")

Activate-Device("Activate input <br>device")

LED-Q{"Is the Power LED ON?"}

PWR-Q{"Measure voltage <br>at PWR BUS (J9):<br><br>Is voltage >14 V?"}

IOCard-Detect-Q{"Is input device detected <br>(CDI Event, <br>Card I/O line low)?"}

Simulated-Input-Q{"Temporarily short <br>connector pins 1/2 <br>(J1-J8):<br><br>Does the <br>Digital I/O Card <br>detect the <br>input change?"}

Fix-PWR["Check layout <br>power wiring, <br>power supply <br>voltage"]

Fix-CDI["Check Digital I/O <br>Card CDI <br>config information"]

Fix-Device["Bad input device: <br>Check device wiring, <br>polarity, and operation"]

Bad-Board["Likely bad<br>Digital I/O Breakout Board<br><br>Contact builder"]

Success[" Input Device<br>Detection Verified"]

Connect-Power --> LED-Q

LED-Q -- "Yes, power LED is On" --> Connect-Card --> Connect-Device --> Activate-Device --> IOCard-Detect-Q

LED-Q -- "No, power LED is Off" --> PWR-Q

PWR-Q -- "Yes, valid input power" --> Bad-Board

PWR-Q -- "No, invalid input power" --> Fix-PWR

IOCard-Detect-Q -- "Yes, device detected" --> Success

IOCard-Detect-Q -- "No, device not detected" --> Simulated-Input-Q

Simulated-Input-Q -- "Yes, simulated input succesful" --> Fix-Device

Simulated-Input-Q -- "No, simulated input not detected" --> Fix-CDI

Fix-CDI --> Bad-Board

end

%% Color styles

classDef question fill:#d3d3d3,stroke:#333,stroke-width:2px,font-size:16px;

classDef error fill:#FFA07A,stroke:#333,stroke-width:2px,font-size:16px;

classDef success fill:#c6f6c6,stroke:#2c7a2c,stroke-width:2px,font-size:16px;

classDef action fill:lightblue,stroke:#2c7a2c,stroke-width:2px,font-size:16px;

class LED-Q,PWR-Q,Input-Wired-Q,IOCard-Detect-Q,Simulated-Input-Q question;

class Fix-PWR,Fix-CDI,Fix-Device,Bad-Board error;

class Connect-Power,Connect-Card,Connect-Device,Activate-Device action;

class Success success;

Safety Notes

- Disconnect power before making or changing device connections.

- Do not exceed device current limits; max current is limited by the 5 VDC regulator and wiring.

- Use appropriate fusing on the accessory power bus to prevent damage.