NeoPixel Breakout Board Install Guide

Table of contents

Table of contents

Overview

The NeoPixel Breakout Board receives 8 PWM signal lines via RJ45 from the PWM Card and powers up to eight 5 V NeoPixel-compatible LED strips (WS2812, SK6812). Voltage is regulated onboard from AC/DC/DCC input via the accessory power bus.

What’s Needed

| Component | Purpose | |

|---|---|---|

| NeoPixel Breakout Board | Distributes PWM signal and 5 V to each strip | |

| PWM Card | Generates PWM signals for NeoPixel control | |

| Network cable (CAT5/CAT6) | Connects PWM Card to Breakout Board (RJ45) | |

| 1–8 NeoPixel Strips (5 V) | LED output devices receiving signal and power | |

| 2-wire cable | Connects Accessory Power Bus to power input (J9) | (5 V type only) |

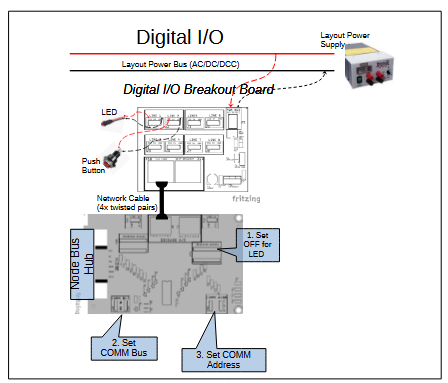

Connection Diagram

flowchart LR

subgraph Train Layout

direction LR

pwm[[PWM Card]]

breakout[[NeoPixel <br>Breakout Board]]

pwrbus("PWR BUS <br>(AC/DC/DCC)")

pixel1["Pixel Strip 1"]

pixel2-8["Pixel Strips 2...8"]

end

pwm -->|"Network Cable → J10"| breakout

pwrbus -->|"2-wire Cable to J9"| breakout

breakout --> |"3-wire → J1"| pixel1

breakout --> |"3-wire → J2...J8"| pixel2-8

Connector Assignments

| Label | Pins | Function |

|---|---|---|

| J1–J8 | 3-pin | Pixel headers (SIG/5V/GND) |

| J9 | 2-pin | Power input (AC/DC/DCC) |

| J10 | RJ45 | PWM input from PWM Card |

Installation Steps

Set PWM Card selector for LINES 7/8 to PWM mode.

Set PWM Card selector for LINES 7/8 to PWM mode.- Connect PWM Card to NeoPixel Breakout Board using RJ45 network cable.

- Connect PWR BUS (J9) to layout accessory power (AC, DC, or DCC).

- Connect 1 or more NeoPixel strips to J1–J8 headers (SIG/5V/GND).

- Note: Pixel signal lines are protected with 1kΩ resistors. Shared 5 V rail protected by SMAJ5.0A TVS + JK30 3A resettable fuse.

- Ensure PWM Card Line 8 is not set to 12 V if connected

- Pixel signal lines are protected with 1kΩ resistors

- Shared 5 V rail protected by SMAJ5.0A TVS + JK30 3A fuse

Status Indicators

- LED1 ON = 5 V output active (power OK)

Testing & Troubleshooting

- Cables & Connections

- Ensure the network cable between the PWM Card and NeoPixel Breakout Board is fully seated and oriented correctly.

- Verify accessory bus voltage and polarity at the board’s power connector.

- Confirm device wiring matches the board pinouts (signal, VDC+, GND).

- Firmware & Diagnostics

- Use the LCC Configuration Monitor (JMRI), serial console, or other diagnostic tool to check that inputs register and outputs toggle as expected.

🧰 Troubleshooting Flow

| Test | Check Point | Expected |

|---|---|---|

| Power LED | LED beside VR1 | LED is ON |

| PWR BUS Voltage | J9 VDC+ → GND | > 12 VDC (AC, DC, or DCC) |

| 5 VDC Regulator | J1–J4 VDC+ → GND | ≈ 5.0 VDC |

| Device Activation | Output lines 1–8 via J10 | Outputs switch on/off; inputs generate LCC Events |

flowchart TD

subgraph "NeoPixel Strip Test Flow"

direction LR

Connect-Power("Connect supply power to <br>PWR BUS connector (J5)")

Connect-Card("Connect <br>Digital I/O Card")

Connect-Device("Connect <br>output devices <br>(lamps, LEDs)<br>to connectors <br>(J1–J8)")

Activate-Device("Activate strip <br>(via LCC Event)")

Activate-Input-Line("Bypass NeoPixel Card: <br>Apply 5 V to each <br>input line (J6)")

LED-Q{"Is the Power LED ON?"}

PWR-Q{"Measure input at PWR BUS (J9).<br><br>Is voltage >14 V?"}

Device-On-Q{"Do connected strips <br>turn ON correctly?"}

Input-Test-Q{"Does the <br>corresponding <br>strip turn ON?"}

Success[[" Installation <br>Successful"]]

Connect-Power --> LED-Q

LED-Q -- "Yes, power LED is On" --> Connect-Card --> Connect-Device --> Activate-Device --> Device-On-Q

LED-Q -- "No, power LED is Off" --> PWR-Q

PWR-Q -- "Yes, valid input power" --> Bad-Board

PWR-Q -- "No, invalid input power" --> Fix-PWR

Fix-PWR["Check layout <br>power wiring, <br>power supply <br>voltage"]

Fix-CDI["Verify NeoPixel card is good. <br>Check cards's <br>CDI configuration"]

Fix-Device["Check strip <br>wiring, polarity,<br>or replace device"]

Bad-Board["Likely bad <br>NeoPixel Breakout Board <br><br>Contact builder"]

Device-On-Q -- "Yes, strip working" --> Success

Device-On-Q -- "No, strip not working" --> Activate-Input-Line --> Input-Test-Q

Input-Test-Q -- "Yes, strip works without <br>NeoPixel Card" --> Fix-CDI

Input-Test-Q -- "No, strip not working" --> Bad-Board

end

%% Color styles

classDef question fill:#d3d3d3,stroke:#333,stroke-width:2px,font-size:16px;

classDef error fill:#FFA07A,stroke:#333,stroke-width:2px,font-size:16px;

classDef success fill:#c6f6c6,stroke:#2c7a2c,stroke-width:2px,font-size:16px;

classDef action fill:lightblue,stroke:#2c7a2c,stroke-width:2px,font-size:16px;

class LED-Q,PWR-Q,Relay-Click-Q,Input-Test-Q,Device-On-Q question;

class Fix-PWR,Fix-CDI,Fix-Device,Bad-Board error;

class Connect-Power,Connect-Card,Connect-Device,Activate-Device,Activate-Input-Line action;

class Success success;

Tips & Warnings

- Never power 12 V pixels from this board

- Allow airflow to LM2596

- Check strip polarity and cable direction

More Info: LCC Fusion Project Documentation

Print Date: ____ **Installer Initials:** ____