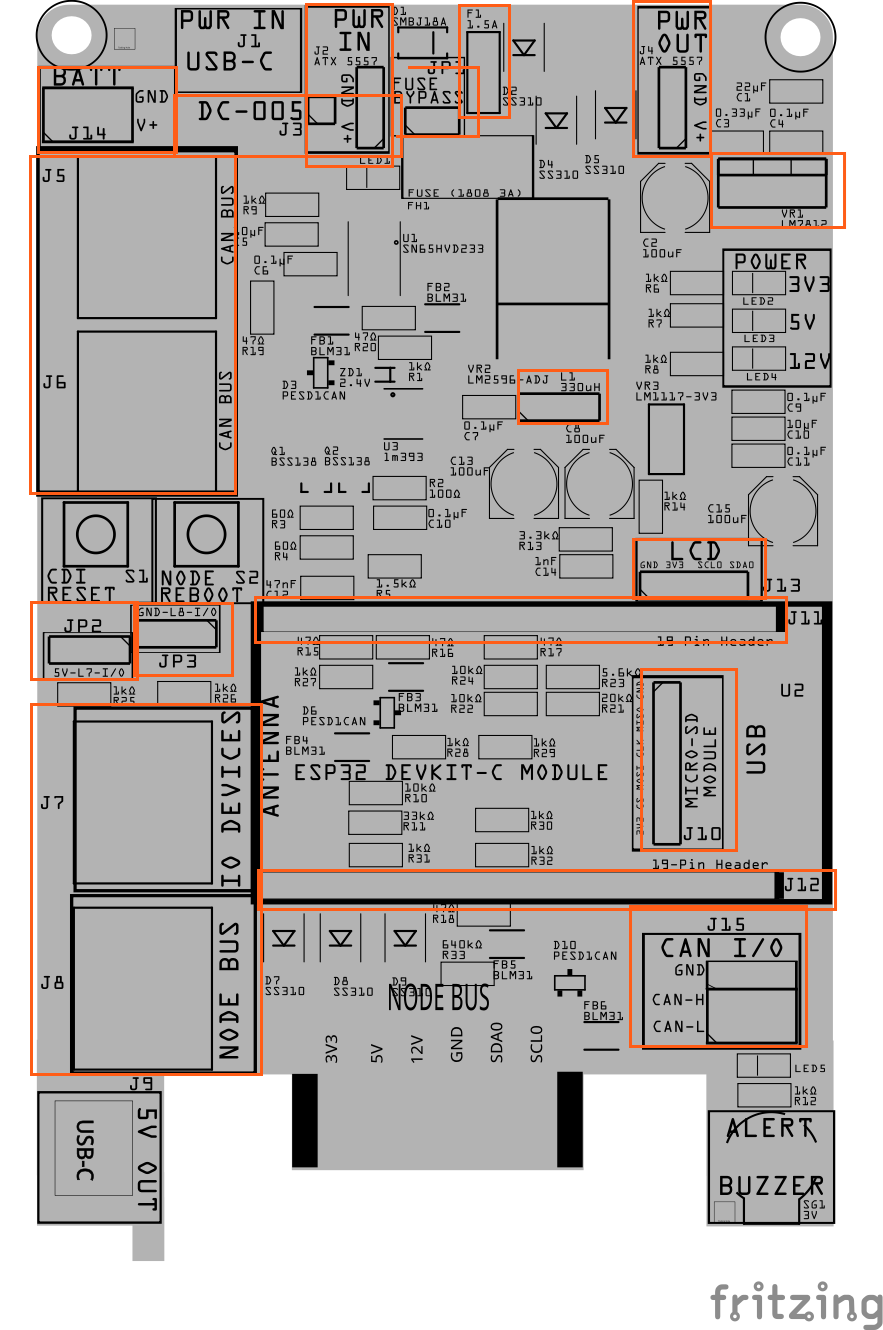

Node Card - Step-By-Step Assembly Guide

[TOC]

Before You Begin

Step 1. Review Configuration Options

Before soldering, determine which options you are building:

- Power input method(s)

- CAN bus connection type

- Node Bus Hub connection (local vs remote)

- I/O device support

- Indicators, buzzer, battery backup, SD card, display

Refer to the Assembly Configuration Options in the Node Card documentation.

Step 2. Gather Tools and Materials

Required Materials

- Node Card PCB and stencil

- PTH and SMD components for your selected configuration

- PCB standoffs (M3, ~11 mm) and nuts

SMD Assembly Tools

- Reflow oven (countertop, digital)

- Solder paste

- Solder paste applicator (syringe, container, or automatic dispenser)

- Paste scraper

- Push pins (for stencil alignment)

- Sticky pickup tool and/or fine tweezers

- Isopropyl alcohol and lint-free wipes

PTH Assembly Tools

- Soldering iron with fine tip

- Solder (PTH components)

Inspection and Handling

- Multimeter

- Magnification (loupe or microscope)

- Foam board or heat-resistant work surface

Step 3. Prepare the PCB

- Inspect the PCB for damage or contamination.

- Clean both sides with isopropyl alcohol.

SMD Assembly

Do not install through-hole components, the ESP32 module, or tall connectors at this stage.

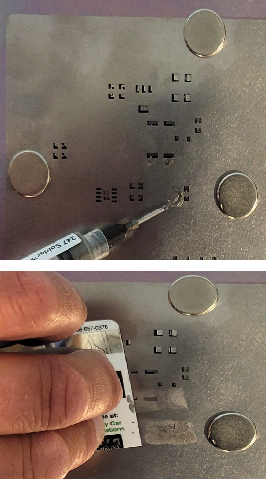

Step 4: Apply Solder Paste

-

Place the PCB flat on 1/4” foam board to support it during stencil work.

-

Position the stencil on top of the PCB and align it using the tooling holes (1.0 mm hole along the top edge and along the bottom edge).

-

Insert push pins through the tooling holes to hold the stencil aligned and in place.

-

Apply solder paste across the stencil openings, then scrape off the excess so paste remains only in the pads.

-

Remove the stencil carefully, lifting straight up to avoid smearing paste.

-

Install the standoffs and nuts now at the four mounting holes using nuts, leaving the board supported and level. This keeps the through-hole leads clear of the surface during reflow

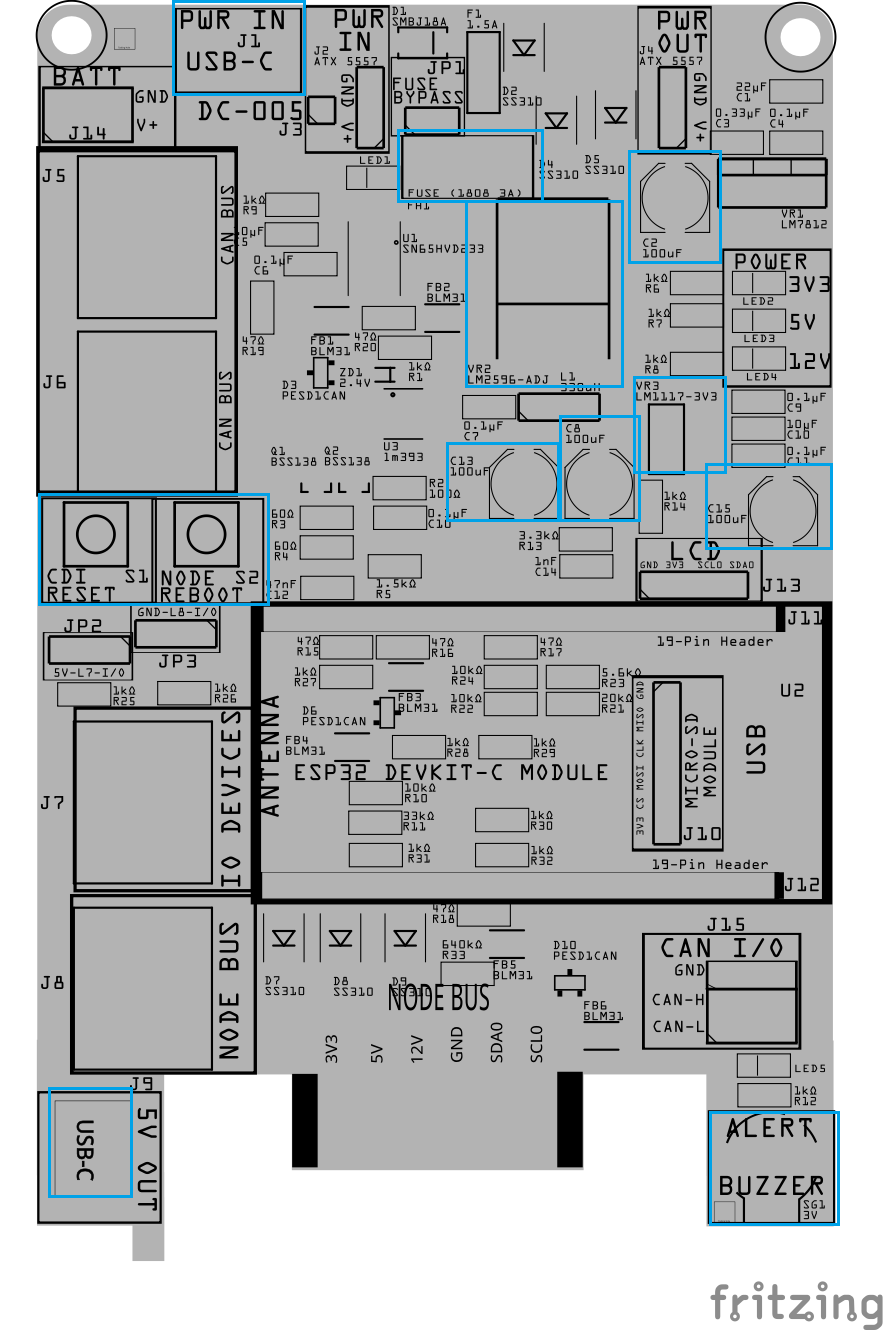

Step 5: Install Small SMD Components (No Orientation Required)

-

Place the small surface-mount components that do not have a direction or polarity.

This includes:

- All resistors (Rx)

- Small ceramic capacitors (Cx)

- Ferrite beads (FBx)

These parts can be placed in either direction, so orientation is not critical.

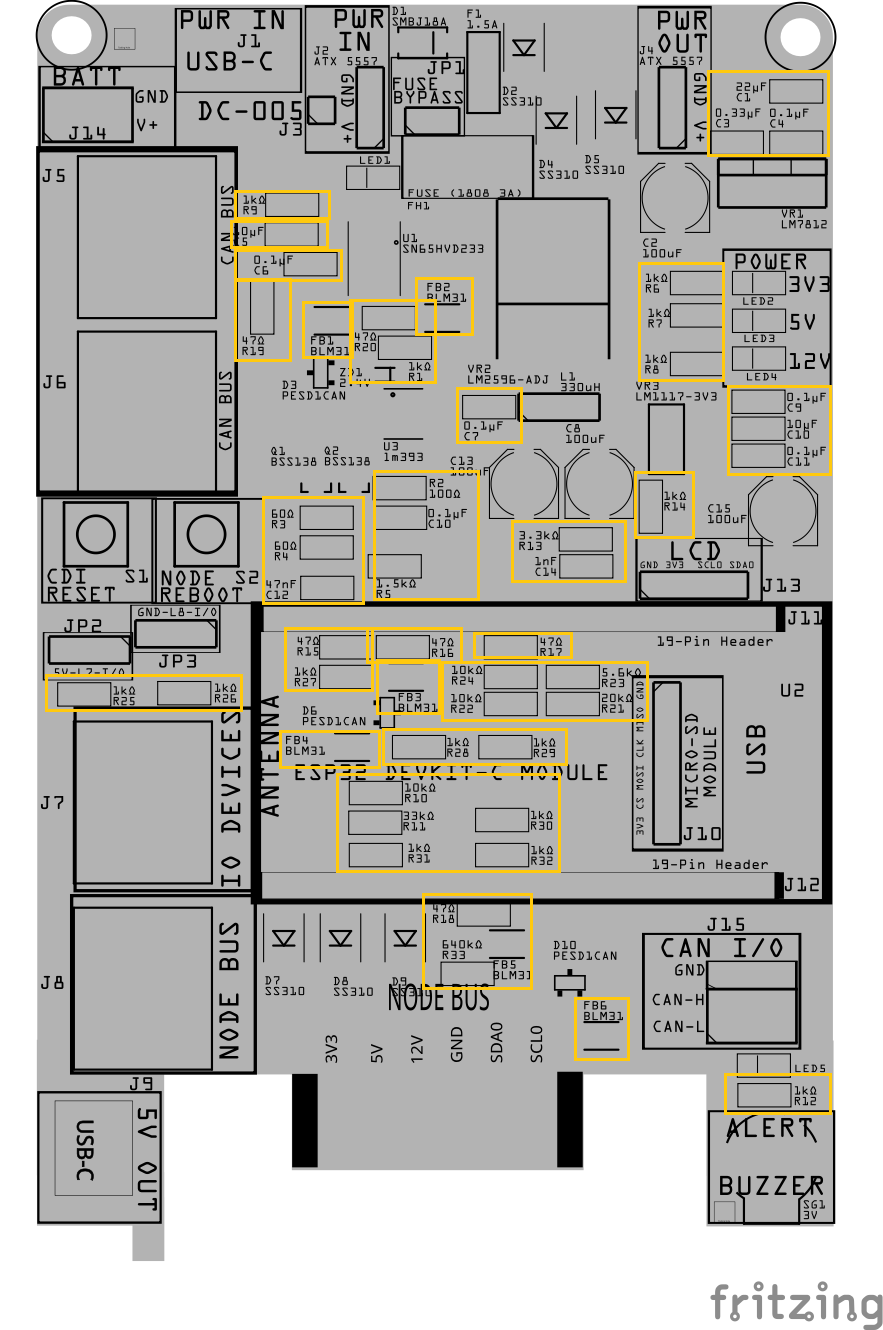

Step 6: Install Small SMD Components (That Have a Direction)

Install the small surface-mount components that must be placed in a specific direction.

This includes:

- Diodes (Dx)

- Zener diodes (ZDx)

- LEDs (LEDx)

- Transistors (Qx)

- PESD1CAN ESD protection diodes (Dx)

- Small ICs (Ux), such as logic or interface chips

These parts must be oriented correctly:

- Match the stripe, dot, or notch on the part

- Align it with the marking on the PCB silkscreen

- For LEDs, refer to the back of the LED for the cathode markings

Take your time with this step—correct orientation here prevents problems later.

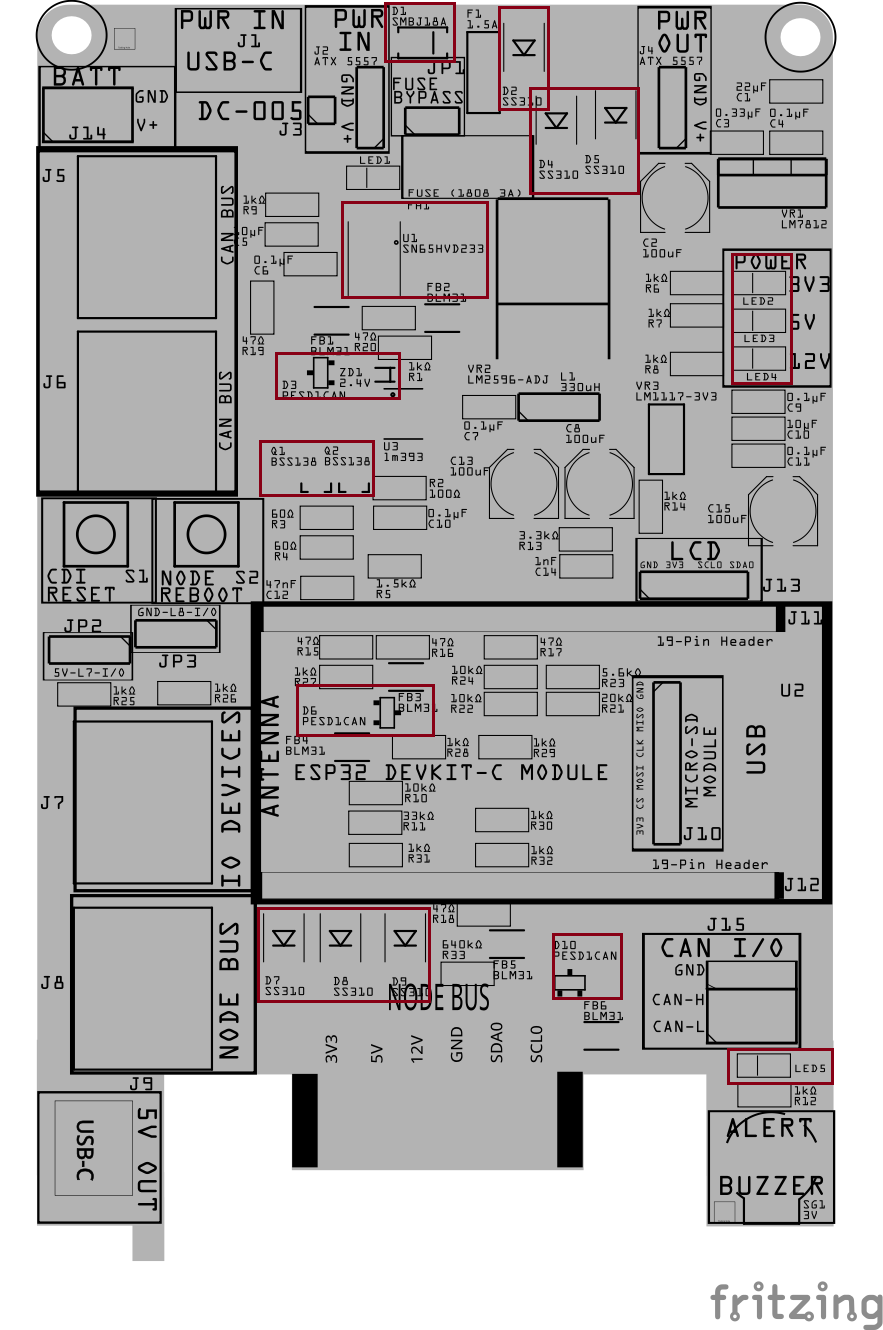

Step 7: Install Larger SMD Components

Install the larger surface-mount components that sit higher on the board and are easier to place once the small parts are done.

This includes:

- Larger polymer or electrolytic capacitors (Cx)

- SMD fuse holder (Fx)

- SMD connectors (Jx), such as USB-C

- Tactile switches (SWx)

- SMD voltage regulators (VRx)

- Buzzer

For polarized parts:

- Match the polarity marking on the component

- Align it with the PCB silkscreen

For connectors and switches:

- Ensure the part sits flat and square on the PCB before reflow

PTH Assembly

Step 8: Install Through-Hole Components

Install the through-hole components while the board is still flat and before reflow.

This includes:

- Fuse (Fx)

- Connectors (Jx), if used

- Inductor (Lx)

- Switches (SWx)

- Female Headers (Jx)

- Male Pins (JPx)

- Voltage regulators (VRx)

To keep these parts from moving during reflow:

- Apply a small amount of solder paste to at least two holes f

- or each through-hole component

- Insert the component fully so it sits flush against the PCB

- The solder paste will hold the part in place during the reflow step

Do not solder the leads yet—final soldering will be done after reflow.

Note: Applying paste to two holes is enough to hold the part during reflow.

Solder PCB

Step 9: Reflow Solder

- Place the board with standoffs into the reflow oven (place tin foil on the wire rack to support the 4x standoffs).

- Reflow the board until all solder paste has flowed and joints appear smooth and shiny.

- Remove the board and allow it to cool naturally. Do not disturb components while the solder is cooling.

- Inspect all solder joints under magnification:

- No solder bridges

- No tombstoned or shifted parts

- Clean, even fillets on pads and leads

Step 10: Solder PTH (Plated Through-Hole Components)

Most PTH components were tacked in place during reflow to hold alignment. This step completes the mechanical and electrical soldering.

- Verify Alignment

- Confirm each PTH component is fully seated onto the PCB.○

- If needed, reheat a single pin and adjust before proceeding.

- Complete Soldering

- Fully solder all pins for each PTH component.

- Ensure solder flows through the hole and wets both the pad and lead.

- Trim and Inspect

- Trim excess lead length.

- Inspect for incomplete fill, lifted pads, or accidental bridges.

- Clean (Optional)

- Remove flux residue if needed to improve visibility for upcoming testing.