Wiring Wheelsets for Enhanced Block Occupancy Detection

Introduction

Wiring a resistor to a model train wheelset for use with current detection is a crucial technique in enhancing the functionality and reliability of track occupancy detection systems. The method described here focuses on an innovative approach that utilizes a 10k ohm 1206 SMD resistor and ‘Wire Glue’ for attachment, offering a neat, solder-free solution. This method is particularly advantageous for its simplicity, effectiveness, and the minimal visual impact on the model train setup.

Advantages of This Technique:

Invisibility: The use of a 10k 1206 SMD resistor is almost invisible when installed, maintaining the aesthetic integrity of the model.

Invisibility: The use of a 10k 1206 SMD resistor is almost invisible when installed, maintaining the aesthetic integrity of the model.- No Soldering Required: This technique eliminates the need for soldering, making it accessible for hobbyists of all skill levels and reducing the risk of heat damage to delicate model components.

- Quick and Easy: The method is fast and straightforward, allowing for efficient modification of multiple wheelsets.

- Improved Detection: Enhances the reliability of track occupancy detection without intrusive modifications to the rolling stock.

This solder-free method of attaching a resistor to a model train wheelset presents a discreet and efficient solution for enhancing current detection systems, ensuring minimal visual impact and maximized functionality for model railroad enthusiasts.

Materials Needed:

| Item | Propose |

|---|---|

| 10k ohm, 1206 SMD Resistor | 10K is required for detection by the BOD Card. SMD is required for gluing 1206 size is the largest SMD and is used for other aspects of the LCC Fusion Project. |

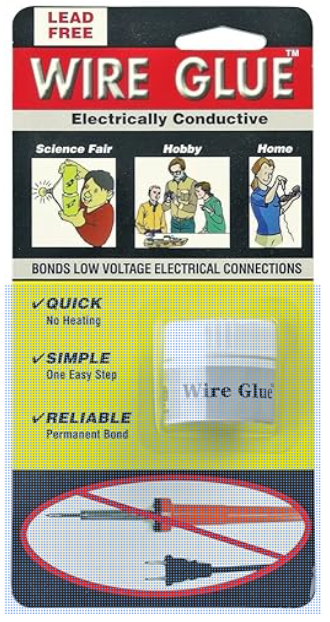

| Electrically Conductive Wire Glue |  Note that not all types work well. This specific brand has great adhesion and conductivity (after a day of drying). Glue on Amazon Note that not all types work well. This specific brand has great adhesion and conductivity (after a day of drying). Glue on Amazon |

| Toothpick or other pointed device | For applying (small) drops of glue. |

| Precision tweezers | For placing the resistor on the axle. |

| Cleaning alcohol and a soft cloth | For preparing the axle and hub for gluing. |

Steps to Wire a Resistor to a Model Train Wheelset:

1. Preparation:

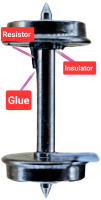

Clean the wheelset axle and hub area thoroughly with alcohol and a soft cloth to ensure a good adhesive bond. Pay special attention to the insulated area between the axle and the wheel hub, as this is where the resistor will be attached.

2. Applying Wire Glue:

Using a toothpick or a similar fine point tool, carefully apply a small amount of ‘Wire Glue’ to:

-

each end of the 10k ohm 1206 SMD resistor. Note that resistor has pads on both the top and bottom. At this point, apply a small amount to just the bottom pad.

-

Add a small drop of glue to the inside of the hub, about an 1/16 inch above the insulator on the axle. Don’t allow the glue to touch or cover the axle.

-

Add a small drop of glue on the axle about an 1/8 inch from the hub.

It’s essential to use just enough glue to make contact without causing excessive spreading that could interfere with the insulator preventing a short across the axle.

3. Attaching the Resistor:

Using precision tweezers, pick up the resistor and position it so that it bridges above the insulated gap between the axle and the wheel hub. The resistor should make contact with the glued surface of the axle on one end and the wheel hub on the other, effectively bypassing the insulation. Carefully press down to ensure a secure attachment.

4. Drying:

Allow the Wire Glue to dry completely for at least one day to ensure the resistor is firmly attached and the glue has set, providing a durable conductive path.

5. Securing the Resistor

To ensure a better electrical contact and to hold the resistor in place better, carefully apply a 2nd drop of glue to both ends of the resistor. This time focus on the resistor’s top pads, spreading the glue across the pad an onto the metal surfaces. Again, let this dry flor a day.

6. Testing:

Once dry, test the connection with a multimeter to ensure conductivity across the wheelset. This confirms the resistor is correctly bridging the insulated gap and will function as intended for current detection.

7. Painting:

Apply a small amount of paint over the area. Use the same color as the axle, possible a rust color if the wheelset is being weathered.

8. Finalizing:

Repeat the process for other wheelsets as required. Once all are prepared and tested, the wheelsets can be installed back on the model train, and the locomotive or rolling stock can be placed on the track to test the overall functionality with your current detection system.